Climate change and new government guidelines sparked major ‘surgery’ on a key hospital department’s ventilation and cooling systems, in a tight four-day operation that included rooftop installation of two Daikin EWAH~TZ air cooled variable frequency drive (VFD) screw compressor chillers utilising HFO Refrigerant.

Successful completion of the project sees the Essex Cardiothoracic Centre (CTC) at Basildon University Hospital, part of Mid and South Essex NHS Foundation Trust, future-proofed against climate change in the foreseeable future.

The four storey building houses the county’s leading facility for heart and lung operations, with four operating theatres, four catheter laboratories (cath labs), MRI and CT scanning facilities, and two 24-bed wards for recovery and in-patient requirements.

The CTC is separated from the main hospital complex by a narrow service road, but connected by an enclosed bridge on the operating theatre level. Two air handling units (AHUs) and two chillers are sited on the CTC roof – effectively a fifth story – close to the road and in line with the bridge.

Iain Oakley, Project Manager for the Mid and South Essex NHS Foundation Trust, says while the CTC’s ventilation and cooling systems had been ‘state of the art’ when switched on in 2009, they had become unable to provide sufficient temperature and humidity control.

“The AHUs had air-on, air-off settings that complied with hospital technical memorandum (HTM) standards at the time. But we know that due to global warming we are often experiencing ambient temperatures in excess of 31oC. There were many days when the cooling capacity simply wasn’t available to meet the demands of the theatres and cath labs.

“We also couldn’t reduce the humidity in the operating theatres, which affected the equipment, occasionally resulting in the theatres and cath labs having to be shut down on days when the humidity was too high, because we could not risk the equipment failing during operations.

“The chilling capacity needed to be improved – and the AHUs replaced at the same time because the original units had never achieved the required air-flow rates.”

Engineers from Ellis Building Services were given a four-day weekend to remove the old equipment, then install and commission the new plant – working in a live environment. Managing director James Ellis says the on site team of David Edwards and Ian Cribbs worked with a great attitude to deliver this project for the NHS.

Iain Oakley says: “That was all the time the CTC would allow. The theatres were shut down late on the Wednesday with work having to be finished on time because there was a list of operations scheduled to start at 8:00 am on the Monday.”

Speed was also essential because while the crane was in place, no traffic could use the service road.

The old chillers were craned off first, and the roof of the plant room removed so that the old AHUs could be replaced. Once the new AHUs were positioned inside the plant room and the roof in place, the two new Daikin VFD controlled chillers were lifted into position.

The CTC reopened on schedule on the Monday morning.

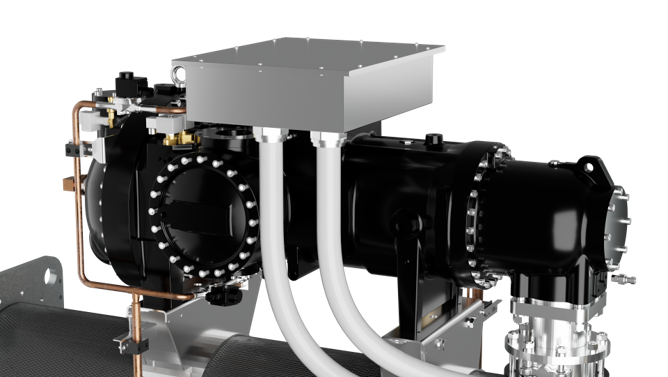

Daikin’s TZ chiller range is the result of careful design, aimed to optimise the operation and the performance of the chiller for comfort and process application in all climate conditions. The objective is to bring down operating costs and improving installation profitability, effectiveness and economical management.

The chillers feature a high efficiency single screw compressor design driven by VFD, a large condenser coil surface area for maximum heat transfer and low discharge pressure, high performance condenser fans and a direct expansion ‘shell and tube’ evaporator with low refrigerant pressure drops.

The combination of these offers the best efficiency at full load and part load operation.

The semi-hermetic, single-screw type compressor with the VFD integrated in the compressor body is designed and manufactured by Daikin. It is the result of years of experience and continuous investment in research and development, optimised to operate with R1234ze(E) refrigerant which has a Global Warming Potential of 7.

The geometry of the compressor itself has been fully redesigned to achieve the highest efficiency at full load delivering the highest part-load efficiency thanks to the VFD allowing continuous modulation of compressor’s rotational speed. The electronics of the VFD are cooled by the refrigerant from the chiller circuit offering a displacement power factor of ≥0.95.

Several additional options were included on the chillers:

· Epoxy polymer coated microchannel coils

· Double pressure relief valves

· Inverter controlled fans

· Energy meters

Kit List

Code | Description | No of Units |

EWAH940TZSSC2 | Daikin AC Inverter Chiller R1234ze(E) | 1 |

EWAH770TZSSC2 | Daikin AC Inverter Chiller R1234ze(E) | 1 |

About Daikin Europe N.V.

Daikin Europe N.V. is a subsidiary of the global group Daikin Industries, and the leading provider of heating, cooling, ventilation, air purification and refrigeration (HVAC&R) technology in Europe, Middle East and Africa. Daikin designs, manufactures, and brings to market a broad portfolio of products, maintenance services as well as turnkey solutions for residential, commercial and industrial purposes. To date, Daikin Europe has over 13,700 employees across more than 57 consolidated subsidiaries. It has 14 manufacturing facilities based in Belgium, the Czech Republic, Germany, Italy, Spain, Austria, the United Kingdom, Turkey, the United Arab Emirates, and the Kingdom of Saudi Arabia. The headquarters of the Daikin Europe group are in Ostend, Belgium. The company was established in 1972, production in Europe started in 1973.

About Daikin Industries Ltd.

Daikin Industries was founded in 1924, in Osaka, Japan. The global group employs over 96,000 people worldwide and is the market leader for heat pump and air conditioning systems and air filtration. It is the world’s only manufacturer that develops and manufactures heating, ventilation, air conditioning and refrigeration equipment, as well as refrigerants in-house. The company achieved € 28.2 billion sales turnover in fiscal year 2022 (1 April 2022 – 31 March 2023).

Media Contacts Daikin Europe N.V.

Sofie Sap – T.: +32 472 580482 Mail: sap.s@daikineurope.com

Daisuke Kakinaga – T.: +32 465 462321 Mail: kakinaga.d@bxl.daikineurope.com